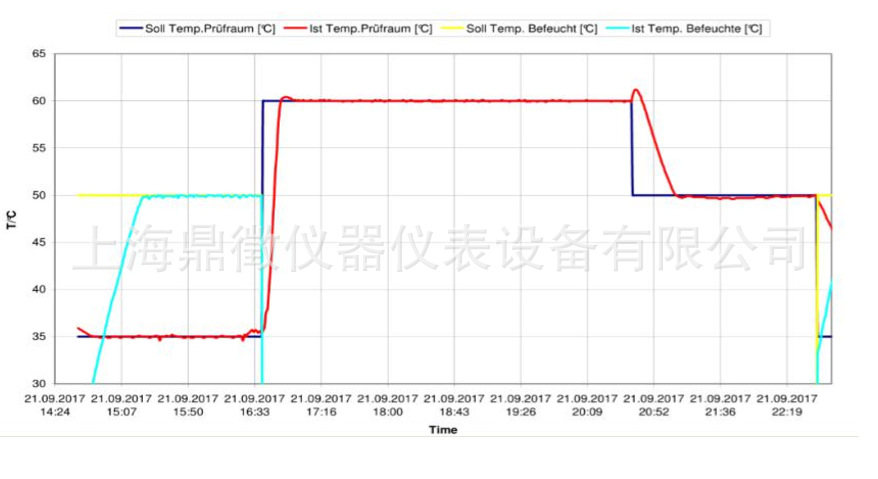

Cycle A

C.1 Salt fog test solution

Prepare the spray solution as described in Clause 5 by dissolving sodium chloride in water to give a concentration of (50±10)g/l .The PH of the solution shall be in the range 6 to 7.

C.2 Cycle

Set up the cabinet to perform the following cycle.

Step | Time H | Temp℃ | Condition | Notes |

1 | 2 | 35±2 | Salt spray |

|

2 | 4 | 60±2 | Dry:20-30% |

|

3 | 2 | 50±2 | Wet:95%RH or over |

|

4 | Go back to step 1 | This makes a total cycle time of 8h from step1 to step3 | ||

| Transtition time(ie time allowed to reach the temperature and relative humidity specified for a condition after changing to that condition): | From salt spray to dry:within 30min From dry to wet:within 150 min From wet to salt spray:within 30min The effect of the salt spray will,in principle,be instaneous。 For details of drying-air flow,see 6.4 | ||

NOTE Set points and operational fluctuations can be listed either independently of each other or in the format:set point±operational fluctuations.The set point is the target condition for the sensor when used at the operational control point as programmed by the user.Operational fluctuations are deviations from the indicated set point at the control point indicated by the readout of the calibrated control sensor during equilibrium operation and do not include measurement uncertainty.At the operational control point , the user programmes that exat number . The operational fluctuations specified for that set point do not imply that the user is allowed to programme a set point higher or lower than the exact set point specified. | ||||

C3 Salt fog depsiton rate

The salt fog deposition rate shall be 1ml/h to 2ml/h,when the salt fog iscollected over a 24h period (see Clause 10)

C 4 Duration

Unless otherwise agreed,repeat the test cycle for 30 cycles(240h),60cycles(240h),90cycles(720h) or 180cycles(1440h)

Cycle B

C.1 Salt fog test solution

Prepare the spray solution as described in Clause 5 by dissolving sodium chloride in water to give a concentration of (50±10)g/l .The PH of the solution shall be in the range 6 to 7.

C.2 Cycle

Set up the cabinet to perform the following cycle.

Step | Time | Temp | Condition | notes |

1 | 24 | 35±2 | Salt fog |

|

2 | 8 | 40±2 | 100%RH | Water condensing on test panels |

3 | 16 | 23±2 | (50±20)%RH |

|

4 | 8 | 40±2 | 100%RH | Water condensing on test panels |

5 | 16 | 23±2 | (50±20)%RH |

|

6 | 8 | 40±2 | 100%RH | Water condensing on test panels |

7 | 16 | 23±2 | (50±20)%RH |

|

8 | 8 | 40±2 | 100%RH | Water condensing on test panels |

9 | 16 | 23±2 | (50±20)%RH |

|

10 | 48 | 23±2 | (50±20)%RH |

|

11 | Go back to step 1 | This makes the total cycle time 7 days from step1 to step10. | ||

NOTE Set points and operational fluctuations can be listed either independently of each other or in the format:set point±operational fluctuations.The set point is the target condition for the sensor when used at the operational control point as programmed by the user.Operational fluctuations are deviations from the indicated set point at the control point indicated by the readout of the calibrated control sensor during equilibrium operation and do not include measurement uncertainty.At the operational control point , the user programmes that exat number . The operational fluctuations specified for that set point do not imply that the user is allowed to programme a set point higher or lower than the exact set point specified. | ||||

C3 Salt fog depsiton rate

The salt fog deposition rate shall be 1ml/h to 2ml/h,when the salt fog iscollected over a 24h period (see Clause 10)

C 4 Duration

Unless otherwise agreed,repeat the test cycle for 840 h

Cycle C

C.1 Salt fog test solution

Prepare the spray solution as described in Clause 5 by dissolving sodium chloride in water to give a concentration of (0.31±0.01)g/l and (4.1±0.01)g/l respectively .The PH of the solution shall be in the range 6 to 7.

C.2 Cycle

Set up the cabinet to perform the following cycle.

Step | Time min | Temp ℃ | Condition | notes |

1 | 210 | 30±2 | Salt fog |

|

2 | 210 | 40±2 | Dry | Drying-air purge(see 6.4) |

3 | 1470 | 40±2 | (75±15)%RH | One method of achieving this conditon is to alternate the dry and humid cycles for suitable(short)time periods to keep the RH between the limits specified |

4 | 102 | 30±2 | Dry | Drying-air purge(see 6.4) |

5 | 210 | 30±2 | Salt fog |

|

6 | 378 | 30±2 | 90% to 100%RH | Water condensing on test panel |

7 | 180 | 35±2 | Dry | Drying-air purge(see 6.4) |

8 | 120 | 25±2 | Dry |

|

9 | Go back to step 1 | This makes the total cycle time 48h from step1 to step8. | ||

NOTE Set points and operational fluctuations can be listed either independently of each other or in the format:set point±operational fluctuations.The set point is the target condition for the sensor when used at the operational control point as programmed by the user.Operational fluctuations are deviations from the indicated set point at the control point indicated by the readout of the calibrated control sensor during equilibrium operation and do not include measurement uncertainty.At the operational control point , the user programmes that exat number . The operational fluctuations specified for that set point do not imply that the user is allowed to programme a set point higher or lower than the exact set point specified. | ||||

C3 Salt fog depsiton rate

The salt fog deposition rate shall be 2ml/h to 4ml/h,when the salt fog iscollected over a 24h period (see Clause 10)

C 4 Duration

Unless otherwise agreed,repeat the test cycle for1000h

Cycle D

C.1 Salt fog test solution

Prepare the spray solution as described in Clause 5 by dissolving sodium chloride in water to give a concentration of (50±10)g/l .The PH of the solution shall be in the range 6 to 7.

C.2 Cycle

Set up the cabinet to perform the following cycle.

Step | Time H | Temp℃ | Condition | Notes |

1 | 0.5 | 30±2 | Salt spray |

|

2 | 1.5 | 30±2 | Wet:(95±3)%RH |

|

3 | 2 | 50±2 | Hot dry |

|

4 | 2 | 30±2 | Warm dry |

|

5 | Go back to step 1 | This makes a total cycle time of 6h from step1 to step4 | ||

| Transtition time(ie time allowed to reach the temperature and relative humidity specified for a condition after changing to that condition): | From salt spray to wet:within 10min From wet to hot dry:within 15 min From hot dry to salt warm dry:within 30min From salt warm dry to salt spray:instaneous | ||

NOTE Set points and operational fluctuations can be listed either independently of each other or in the format:set point±operational fluctuations.The set point is the target condition for the sensor when used at the operational control point as programmed by the user.Operational fluctuations are deviations from the indicated set point at the control point indicated by the readout of the calibrated control sensor during equilibrium operation and do not include measurement uncertainty.At the operational control point , the user programmes that exat number . The operational fluctuations specified for that set point do not imply that the user is allowed to programme a set point higher or lower than the exact set point specified. | ||||

C3 Salt fog depsiton rate

The salt fog deposition rate shall be 1ml/h to 2ml/h,when the salt fog iscollected over a 24h period (see Clause 10)

C 4 Duration

Unless otherwise agreed,repeat the test cycle for 28 cycles(168h)

免責聲明

- 凡本網注明“來源:化工儀器網”的所有作品,均為浙江興旺寶明通網絡有限公司-化工儀器網合法擁有版權或有權使用的作品,未經本網授權不得轉載、摘編或利用其它方式使用上述作品。已經本網授權使用作品的,應在授權范圍內使用,并注明“來源:化工儀器網”。違反上述聲明者,本網將追究其相關法律責任。

- 本網轉載并注明自其他來源(非化工儀器網)的作品,目的在于傳遞更多信息,并不代表本網贊同其觀點和對其真實性負責,不承擔此類作品侵權行為的直接責任及連帶責任。其他媒體、網站或個人從本網轉載時,必須保留本網注明的作品第一來源,并自負版權等法律責任。

- 如涉及作品內容、版權等問題,請在作品發表之日起一周內與本網聯系,否則視為放棄相關權利。

手機版

手機版 化工儀器網手機版

化工儀器網手機版

化工儀器網小程序

化工儀器網小程序

官方微信

官方微信 公眾號:chem17

公眾號:chem17

掃碼關注視頻號

掃碼關注視頻號

采購中心

采購中心